pharmaceutical grade CMC

1.Sodium Carboxymethyl Cellulose(CMC) for Pharmaceutical Industry

Sodium Carboxymethyl Cellulose for Pharmaceutical Industry.Sodium Carboxymethyl Cellulose is widely used in Pharmaceutical Industry. If added Sodium Carboxymethyl Cellulose into medicine table or gain as adhesive and disintegrant, the medicine will be easily processed into some shape and it is the medicines to digestion and absorption, Sodium Carboxymethyl Cellulose can also be used in ointment as dispersant and humectant, and in some syrup, etc., used as suspending agent, emulsifier, stabilizer and so on.If added Sodium Carboxymethyl Cellulose into medicine table or gain as adhesive and disintegrant, the medicine will be easily processed into some shape and it is the medicines to digestion and absorption, Sodium Carboxymethyl Cellulose can also be used in ointment as dispersant and humectant, and in some syrup, etc., used as suspending agent, emulsifier, stabilizer and so on.

2.Commodity Name: Sodium Carboxymethyl cellulose

CAS No.: 【9004-32-4】

Molecular formula :[C6H7O2(OH)2OCH2COONa]n

Synonyms: Carboxymethyl Cellulose, Carboxy Methyl Cellulose, CMC, Sodium CMC, Na-CMC

HS Code: 39123100

3.Description

Sodium Carboxymethyl Cellulose is a cellulose derivative with carboxymethyl groups bound to some of the hydroxyl groups of the glucopyranose monomers that make up the cellulose backbone. It is often used as its sodium salt, sodium carboxymethyl cellulose.

4.Type and Specifications

Pharmaceutical Grade CMC

Types SpecificationPG1PG2PG11PG12

AppearanceWhite or Yellowish Powder

D.S0.7-0.9

Viscosity (mPa.s)400-800800-1200800-12001200-2000

2% solution testing1% solution testing

PH (25°C)6.5-8.5

Moisture(%)≤8.0

5.Properties

1. Thickening: CMC can produce high viscosity at low concentration. It also acts as lubricant.

2. Water retention: CMC is a water binder, helps increase shelf life of food.

3. Suspending aid: CMC acts as emulsifier and suspension stabilizer, particularly in icings to control ice crystal size.

4. Film forming: CMC can produce a film on the surface of fried food, eg. instant noodle, and prevent absorption of excessive vegetable oil.

5. Chemical stability: CMC is resistant to heat, light, mold and commonly used chemicals.

| Types /Specification | PG1 | PG2 | PG11 | PG12 |

| Appearance | White or Yellowish Powder | |||

| D.S | 0.7-0.9 | |||

| Viscosity (mPa.s) | 400-800 | 800-1200 | 800-1200 | 1200-2000 |

| 2% solution testing | 1% solution testing | |||

| PH (25°C) | 6.5-8.5 | |||

| Moisture(%) | ≤8.0 | |||

6. Physiologically inert: CMC as a food additive has no caloric value and can not be metabolized.

6.Package

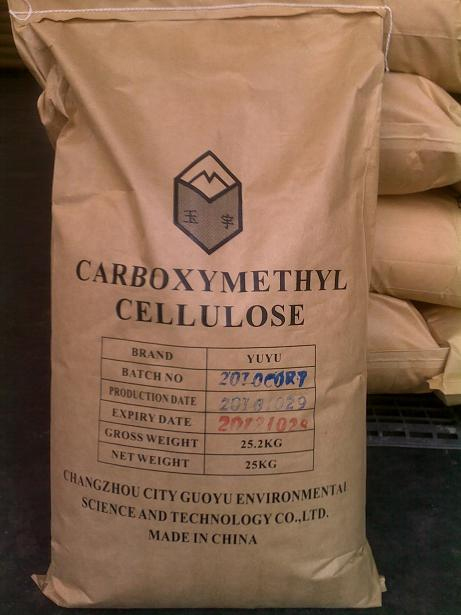

Packing:25kg kraft paper bag, or other packing as clients request.

7.Storage

1.Store in a cool, dry, clean, ventilated environment.

2.The product for pharmaceutical and food grade should not be put together with toxic substance and harmful substance or substance with peculiar smell during transportation and storage.

3. Since the date of production, a preservation period should not exceed 4 years for the industrial product and 2 year for the product for pharmaceutical grade.

4. The products should be prevented from water and package bag damaging during transportation.

We can produce food grade Sodium Carboxymethyl Cellulose with high purity, very high viscosity according to the customer's requirements

- Previous:Textile printing grade CMC

- Next:Paper-making grade CMC